Coopers Fire offer Monthly CPD seminars on fire curtains

Find out more and sign up for the next monthly Coopers Fire CPD seminar.

Wedding Venue Fire Safety

A wedding day is one of the most special memories a couple will experience together. However, amongst the joyous celebrations,…

Electric Vehicle Fires: Safety Precautions

Electric vehicles (EVs) are a sustainable and promising alternative to traditional petrol-powered cars that have hugely increased in popularity in…

New Product: The FireMaster Insul8 – Where Innovation Meets Unmatched Reliability

Coopers Fire are proud to launch their insulated fire curtain - the FireMaster Insul8

Introducing the Pioneering FireMaster Concertina with Smoke Control

The first and only Concertina fire curtain available with smoke control to BS EN 1634-3 and Certified to BS 8524

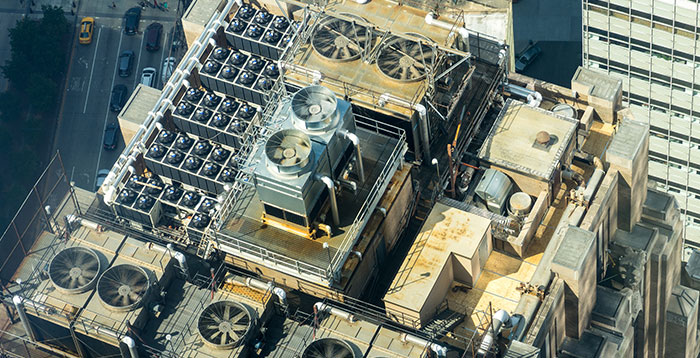

How to Prevent Sprinkler Systems Freezing in the Winter

As temperatures grow colder and the winter months are upon us, it is crucial to start thinking about sprinkler system…

UKCA / CE Marking of Operable Fabric Curtains (fire curtains)

The ASFP have recently updated their Technical Guidance Document 21 on the subject of 'UKCA / CE Marking of Operable…

What is the True Cost of a Closed Business Due to Fire?

A fire can be a devastating event for any business owner. Not only does it pose immediate risks to the…

Coopers Fire Raise Money for Macmillan Coffee Morning

Coopers Fire raised £198.13 at their recent Macmillan Cancer Support Bake Sale.

The Great South Run for the Fire Fighters Charity

A TEAM OF RUNNERS TAKE ON THE GREAT SOUTH RUN

Fire Protection for Cruise Ships

Cruise ships offer passengers the allure of luxurious travel on the high seas, with the promise of unforgettable experiences and…

Understanding Human Behaviour in Fire Emergencies: Enhancing Evacuation Strategies

Fire emergencies are critical situations that can pose significant risks to the safety and well-being of occupants in buildings, and…

Fire Safety for Remote Work: Ensuring Protection in the Virtual Workspace

As the world rapidly embraces remote work, the concept of traditional office space is gradually fading away.

Fire Safety in the Digital Age: How Technology is Transforming Fire Protection

In today's digital age, technology has taken over almost every aspect of our lives, including fire safety and protection.

Big Hike South Coast for Cancer Research UK

Coopers Fire Take ON The Big Hike South Coast for Cancer Research UK

Coopers Fire Achieve FIA Approval for CPD Material

Coopers Fire are proud to announce they have achieved FIA approval for CPD material for Active Fire curtain Barriers

New Forest Sportive for the British Burn Association

Coopers Fire Team Takes on a the New Forest Sportive for the British Burn Association.

Mental Health Awareness Week – May 2023

As part of Mental Health Awareness Week Coopers Fire raised £190 for The Mental Health Foundation.

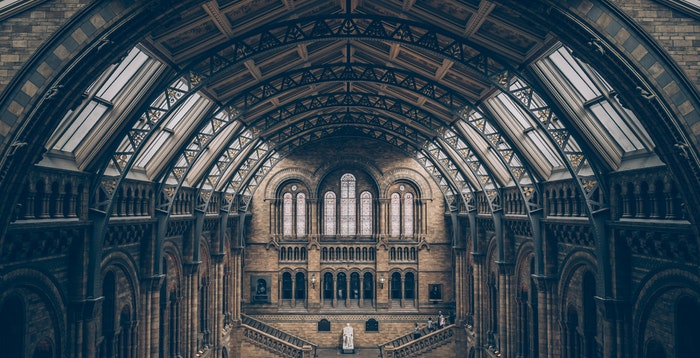

Fire Protection in Historic Buildings

Historic buildings are an essential part of the cultural heritage of the world.

Celebrating King Charles coronation

As His Majesty The King is crowned as Head of State, Coopers Fire expresses its congratulations and warmest wishes for…

Come and see Coopers Fire at Firex 2023

Coopers Fire are exhibiting at Firex 2023 from Tuesday 16th May to Thursday 18th May on stand FI.1240 REGISTER FOR…

Football Stadium Fire Safety – Learning Lessons

Football is one of the most popular sports in the world, and it is enjoyed by millions of people.

Coopers Fire are exhibiting at The Fire Safety Event 2023

Coopers Fire are exhibiting at The Fire Safety Event 2023 on Stand 3a/h22 from Tuesday 25th to Thursday 27th April…

Coopers Fire Easter collection for Waterlooville foodbank

Coopers Fire are proud to have organised another EGG-cellent Easter collection for Waterlooville Foodbank.

5 Hidden Fire Hazards in The Home

Fire hazards in the home are more common than you think. They can happen anywhere, but many often forget that one…

News Article: Setting the standard – why British Standard BS 8524 is the definitive guide for fire curtains

Technical Director Ray Kerry explains the important role of standards in ensuring the quality, safety and performance of active fire…

The Importance of Emergency Lighting

Emergency lighting is a crucial element of fire safety in buildings.

Coopers Fire are certified to ISO 45001 for Health and Safety

Coopers Fire have added ISO 45001 Occupational Health and Safety Management to our other LRQA Certification for ISO 9001 and…

Coopers Fire Raise Money for Four Paws UK

For January's monthly charity Coopers Fire raised £298 for Four Paws UK who provide safe homes for wildlife.

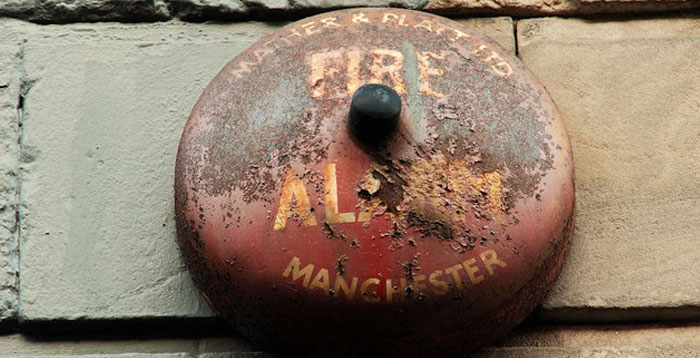

The Cost of a False Fire Alarm

A false fire alarm can have damaging consequences for businesses, both financially and in terms of safety. Not only can…

Christmas Fire Safety in 2022

It's that time of year again - the Christmas period is around the corner and the exciting festivities await us.

Coopers Fire Christmas Charity Collections

For Christmas 2022, Coopers Fire Supported Save The Children and the Waterlooville Food Bank

Coopers Fire Raise Money for the Fire Fighters Charity

Coopers Fire raised £1,400 for the Fire Fighters Charity by taking part in the Great South.

Product News: FireMaster Concertina Egress tested to BS EN 1634-1

Coopers Fire is proud to announce the launch of the FireMaster Concertina Egress fire curtain that has been tested and…

Coopers Fire Win ASFP Award 2022

Coopers Fire are really proud to announce that we won the Association for Specialist Fire Protection (ASFP) award for Best…

Fireworks and Bonfire Safety

As bonfire night draws closer and the exciting festivities begin, a firefighter’s busiest time of year quickly approaches.

Coopers Fire Raise Money for Macmillan Cancer Support

Coopers Fire raised £380 for Macmillan Cancer Support with their coffee morning and charity dress down day.

Environmental Impact of Fire: The Cost of a Burning Building

Fires in buildings are known to cause significant damage to the environment and encourage already rising pollution levels - sometimes…

Coopers Fire Adopt Mable and Archie and Raise Money for the IOW Donkey Sanctuary

Coopers Fire August charity dress down raised £180 for the Isle of Wight donkey sanctuary and enabled us to adopt Mable…

The Dangers of Smoke Inhalation

Smoke can release dangerous chemicals, depending on what is burned, fire temperature and how much oxygen is surrounding the fire.

Coopers Fire Food Bank Appeal

Coopers Fire are really pleased to have been able to support Waterlooville foodbank again this summer.

Coopers Fire Raise Money for Cancer Research UK

Coopers July charity dress down raised £154 for Cancer Research UK

Fire Safety in Construction

With many hazardous activities comes the risk of fire. In the construction industry, the level of risk is much higher,…

Fire Extinguisher Guide: What you need to know

Fire extinguishers are an essential piece of fire safety equipment.

Coopers Fire Raise Money for RNLI

Coopers June charity dress down raised £128 for RNLI : Royal National Lifeboat Institution

Guide to BS 8524 Fire Curtains

Fire safety and protection are more prevalent than ever before. There is a huge push on competency and compliance for…

Coopers Fire Raise Money for the Mental Health Foundation

As part of Mental Health Awareness Week Coopers Fire raised £200 for The Mental Health Foundation

Coopers Fire raise money for Alzheimer’s Society

Coopers Fire raise £396 for Alzheimer’s Society with a bake sale and dress down day!

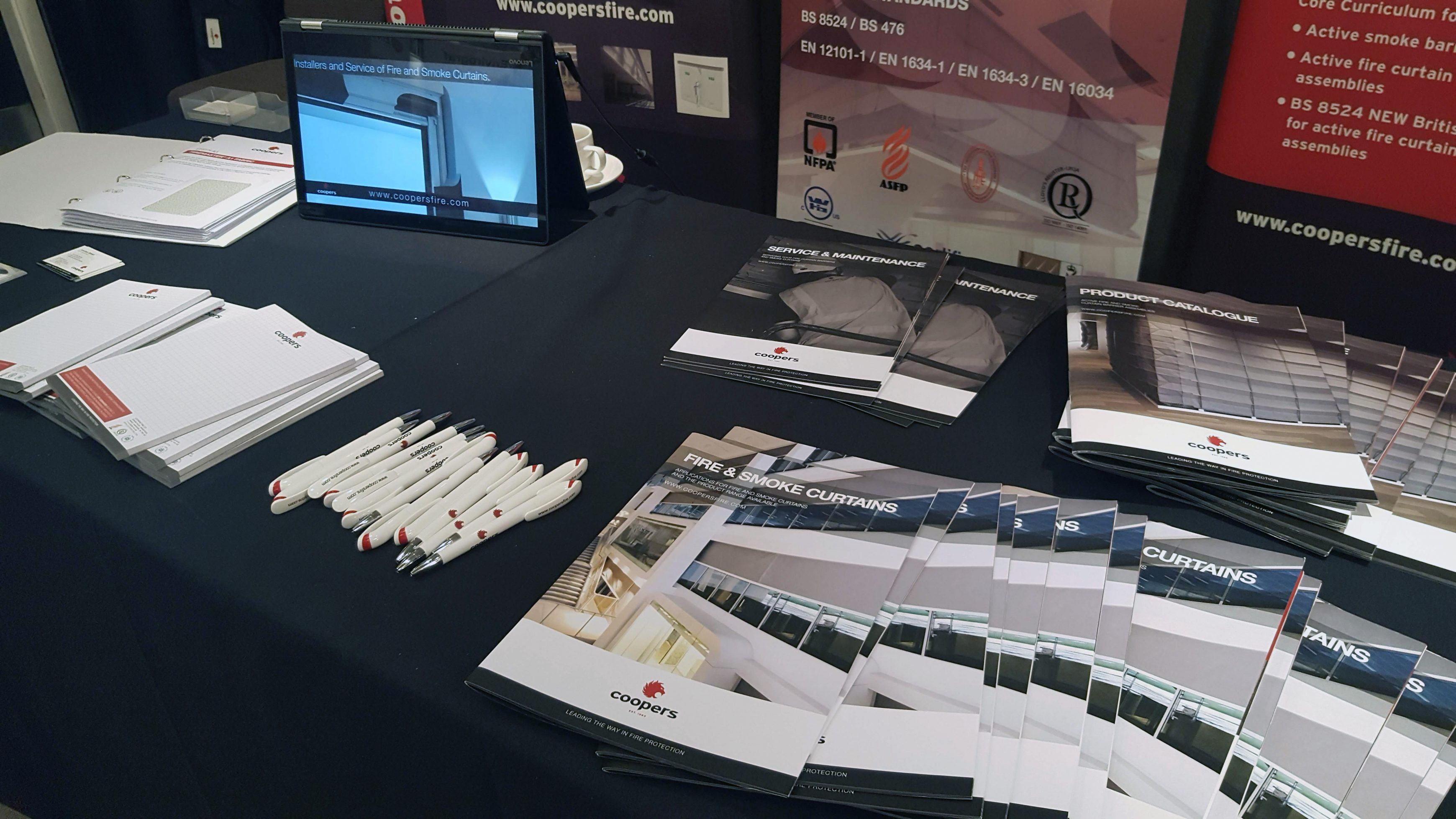

Coopers Fire exhibit at Intersec 2023

From January 17-19 2023, Coopers Fire will be exhibiting at Intersec in Dubai, the world-leading emergency services, security and safety…

Coopers Fire are exhibiting at Firex 2022!

Coopers Fire are returning to Firex International 2022 from Tuesday 17th May to Thursday 19th May. Register for free tickets

Coopers Fire Easter Appeal

Coopers Fire’s Easter appeal collected chocolate Easter eggs and high demand food items for Waterlooville food bank this Easter.

The History of Fire Safety Legislation

Fire safety legislation is an incredibly crucial part of ensuring the UK is kept safe from fire as much as…

Coopers Fire Raise Money for Kidney Research UK

Coopers Fire raised £144 for Kidney Research UK. In support of World Kidney Day on the 10th of March Coopers…

Fire Safety in Care Homes: A 2022 Guide

Fire safety in care homes must take top priority to ensure the well-being of all residents, staff and visitors in…

New Powder Coating Line at Coopers Fire

Coopers Fire benefit from in house powder coating line

Coopers Fire Raise Money for Hearing Dogs for Deaf People

In February Coopers Fire raised £313 for Hearing Dogs for Deaf People.

Coopers Fire Exhibitions Calendar for 2022

Over the course of the year, throughout the UK, Coopers Fire will be attending and presenting at a wide range…

Hotel Fire Safety: What you need to know

Hotel fire safety is an essential factor in the hospitality sector.

The Importance of Fire Safety Training

Fire safety training is vital in any environment, but fire safety training in the workplace is essential for any business…

Coopers Fire Raise Money for Juvenile Diabetes Research Foundation

coopers fire January’s charity dress down day raised £260 for Juvenile Diabetes Research Foundation Ltd (JDRF).

The Importance of Fire Safety Signage in a Commercial Building

While you may not notice fire safety signs immediately as you enter a building, they are an essential factor in…

Fire Safety in Hospitals: What you should know

Fire safety in hospitals is incredibly important, considering the care required for vulnerable people within such facilities.

Common Causes of False Fire Alarms

In 2020, 42% of FRSs incidents attended were due to false fire alarms.

Coopers Fire Christmas Charity appeal 2021

This year Coopers supported four charities in the lead up to Christmas Charity appeal in December. Staff at Coopers have…

Be Aware of Winter Fires: Christmas Fire Safety

As we celebrate the upcoming festive season and the colder evenings, Christmas fire safety is an essential consideration before you…

Fire vs. Smoke Curtains: What are the Differences?

Make sure you choose the right protection from fire and smoke, in line with your specific requirements.

Are Smoke Detectors Fire Control Measures?

Smoke detectors are a well-established legal requirement for commercial buildings.

Coopers Fire raise money for Combat Stress

November’s charity dress down day raised £100 for Combat Stress

Coopers Fire volunteer for the day at Aldingbourne Trust!

Coopers Fire take part in their first volunteering day at the Aldingbourne Trust.

Coopers Fire shortlisted for the ASFP Best Installation Project

Coopers Fire are proud to have been shortlisted for the Association for Specialist Fire Protection (ASFP) award for Best Installation…

Coopers Fire Raise Money for SANDS

Coopers Fire raised a phenomenal £450 for Sands: Stillbirth and neonatal death, by holding a dress down day and raffle…

How to keep schools safe to prevent the risk of fire

With any fire, the safety of the building and the residents inside are at the forefront of concern. The cost…

Smoke Protection for Elevators in Commercial and Residential Buildings

Elevators in commercial and residential buildings require a high level of fire protection to keep occupants safe during a fire.

Coopers Fire are exhibiting at London Build 2021

Coopers Fire are returning to London Build 2021 at London Olympia from Wednesday 17th November to Thursday 18th November 2021.…

Fire Safety Management for Unoccupied Buildings

As the owner of an empty commercial building, you are responsible for putting fire safety measures in place.

The Importance of a Fire Evacuation Checklist

A fire evacuation plan is an essential document that ensures the safety of those in the workplace.

Coopers Fire raise money for Macmillan Cancer support

Coopers Fire raised a massive £246 for Macmillan Cancer Support with their coffee morning and charity dress down day.

Coopers Fire raise money for The Children’s Burns Trust

For August’s Charity of the Month, Coopers Fire raised £60 for The Children’s Burns Trust For August’s Charity of the…

Dealing with the Aftermath of a House Fire

Dealing with the aftermath of a house fire can be distressing for everyone involved.

Top Fire Safety Tips to Stay Safe this Summer

With the summer months finally, here, it is essential to think about the safety precautions you should take to prevent…

How Technology May Change Fire Protection and Rescue in 2021

The fire protection and rescue industry can be known to move slower than other industries due to the struggle with…

Coopers Fire are re-certified for ISO 9001 and ISO 14001

Coopers Fire are pleased to announce that they have been re-certified for ISO 9001 Quality Management System (QMS) and ISO…

Coopers Fire raise money for The Hygiene Bank

As part of National Hygiene Week (5th - 11th July) Coopers Fire staff held a charity dress down day and…

Most Common Causes of Commercial Fires

Although fire may not be the most common type of workplace accident in the UK, the danger of experiencing such…

Coopers Fire participate in Kickstarter Scheme

Coopers Fire have recently welcomed two new starters to the Coopers Fire team who are part of the Kickstarter scheme.

Coopers Fire raise money for the Cystic Fibrosis Trust

Coopers Fire staff at Ignis House took part in national Wear Yellow Day in support of the Cystic Fibrosis Trust…

Why the Great Fire of London probably won’t happen in the 21st century

In the early hours of the morning of September 2nd in 1666, a fire started at a bakery on Pudding…

How to Protect your Premises from Arson

Arson has been a nuisance to many people for many years. The burden of economic loss to people, local authorities,…

Fire Curtain Maintenance – Expert Advice

Fire curtains are an incredibly efficient way to keep buildings safe from fire and smoke damage without compromising on building…

Coopers Fire at Firex Connect 2021

Coopers Fire will be virtually online at Firex Connect 2021 booking online meetings throughout June 2021.

Why Does a Building need Fire Curtains?

The implementation of fire-resistant barriers, such as fire doors and curtains, into a building’s design divides space into compartments.

Coopers Fire raise money for MIND for Mental Health Awareness Week

For mental health awareness week, coopers fire raised £100 for mind charity.

Coopers Fire Appoint Distributor in the Kingdom of Saudi Arabia

Coopers Fire are pleased to announce the appointment of Energy & Building Masters (EBM) as an official distributor in THE…

Coopers Fire raise money for the Oddballs Foundation

For April's charity of the month, Coopers Fire raised £110 for the Oddballs Foundation.

How is Arson Detected? The Forensic Science of Fire

When investigating a crime scene with fire involved, detecting arson takes clear consideration, prompt analysis and efficient detection.

Coopers Fire Exhibition Calendar for 2021

Coopers Fire will be present at a variety of different UK exhibitions and conferences throughout 2021.

Your Fire Safety Checklist for Reopening after Lockdown

It has been a while since we last discussed the retail and hospitality industry being back in business. But, with…

Gov Data Shows Regions with the WORST Fire Safety Inspections

Coopers Fire has investigated the latest fire prevention and protection statistics for England, for the year ending March 2020.

HRH Prince Philip, The Duke of Edinburgh, 1921-2021

Red Nose Day 2021

On Friday 19th March we asked everyone to wear something red to work in support of Red Nose Day for…

Can Fire Burn Forever?

Nothing can last forever – including a fire. Eventually, the fuel source will be exhausted and the heat will radiate…

Class A to K – What are the Classes of Fire?

Our deep knowledge and understanding of fire is how we’re able to fight it so effectively – but the classes of…

How Many Fire Exits does a Building Need?

Size and usage can make a difference to the number of fire exits a building requires. But a fire exit…

The Fire Barrier Curtain: Five Generations of Knowledge

Coopers Fire pioneered modern fire protection systems with our first – and the world’s first – automatic smoke curtain. The history…

What do Fire Ratings Mean?

Fire rating systems are a way of determining how much time a passive fire protection system can withstand a fire.…

Coopers Fire Christmas Appeal

In the lead up to Christmas, Coopers Fire have been running a collection for Waterlooville Food Bank.

Christmas, COVID and Fire Safety

Even with slightly relaxed COVID-19 restrictions, Christmas in 2020 will be very different from the ones we’re used to celebrating.…

Coopers Fire Christmas Jumper Day 2020!

On Friday 11th December 2020 Coopers Fire took part in National Christmas Jumper Day in aid of Save the Children…

New RIBA Approved CPD on Cleanroom Fire Curtains

Coopers Fire aRE pleased to announce the launch of our RIBA Approved CPD on Cleanroom Fire Curtains

2020 in Fire Safety: How the Pandemic Impacted Fire Around the World

2020 was a big year for Coopers Fire. We relocated our headquarters to a purpose built, state-of-the-art new facility in…

Coopers Fire Christmas Shutdown

Coopers Fire shutdown details for the 2022 festive period.

Coopers Fire Raise Over £300 for the Royal British Legion Poppy Appeal

On the 20th November, Coopers Fire held a raffle around the office and factory to support the Royal British Legion…

What Makes a Building Impressive?

Beauty is in the eye of the beholder – but in architecture, there are countless examples of buildings that are universally…

Using Concertina Fire Curtains in Complex Interior Designs

Open-plan spaces remain hugely popular in architecture. Giant leaps of engineering achievement have made incorporating large open spaces in modern…

Horizontal Fire Curtains: Uses and Application

Modern commercial structures benefit from the latest architectural, construction and fire safety innovations – giving designers almost limitless possibilities for…

Back in Business: Maintaining Fire Safety After Lockdown

While there’s still a lot up in the air at the moment, some offices have returned to business. But was…

ASFP publish Black Book Guidance on Active Fire Curtains

The Association for Specialist Fire Protection (ASFP) has published its new Black Book: Active Fire Curtains: Compartmentation and Protected Routes,…

Getting Closer to Fire: How Does a Fire Proximity Suit Work?

Most of us would love to gather around a campfire on a cool evening to toast marshmallows, but spend too…

Fire Statistics: When do Most Fires Happen?

Predicting when a fire will happen is a difficult and complex task. Emerging artificial intelligence and machine learning tools could…

The Science of Fire: How it Can Improve Fire Safety

There’s evidence of all early civilisations making strides to control and understand nature. In the beginning, science and magic were…

Megatall Buildings: How to Escape a Fire when You’re a Mile High

In 2009, the exterior structure of the Burj Khalifa was completed. It became the tallest building in the world and…

Fires on Mars? How to Uphold Fire Safety Off-Planet

In May 2020, as the world grappled with life in lockdown and a deadly virus, things couldn’t have looked more…

Every business needs this fire safety equipment

The global coronavirus pandemic threw the world into lockdown. Only now are businesses, schools and places of worship beginning to…

Online CPD Seminars with Coopers Fire

Coopers Fire are now hosting their CPD seminars online through Microsoft Teams and Zoom.

The worst hotel fire in history: What did we learn?

Hotel fires are among the most poignant disasters. Maybe it’s the intimate link between hotels and travel, our connection with…

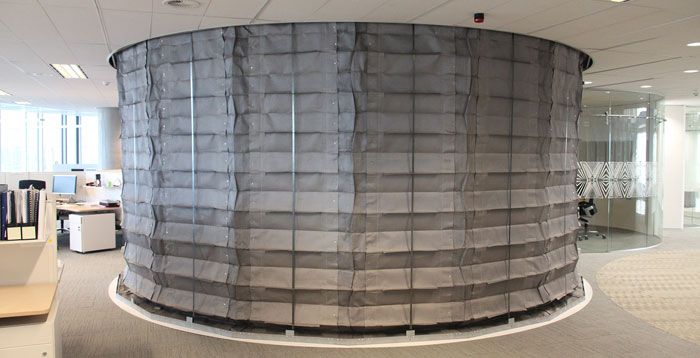

Ignis House; A new home for Coopers Fire

Coopers Fire have moved into their new purpose-built headquarters in Waterlooville, Hampshire.

Buildings of the Future – the Key to Human Survival?

If there’s one thing we’ve learned in the last few months, it’s that the world can change at a moment’s…

COVID-19 – Complying with UK Government Guidance

Coopers Fire are compliant to the UK Government guidance to ensure our workplace is a safe environment.

Singapore’s History With Fire – And A Future Set to Tackle it

On 21 November 1972, a blaze tore through Robinson’s department store at Raffles Place. It started at around 10am, when…

How Are Fire Curtains Made?

We’re proud that all of our fire curtains are built by us at our manufacturing plants in the United Kingdom. But how…

Coopers Fire resume manufacturing

Coopers Fire have continued to closely monitor developments of the Coronavirus pandemic as well as UK Government announcements and as…

Coronavirus (Covid-19) – Coopers Fire Business Statement

Coopers Fire are committed to the welfare of all our employees and the wider communities in which we operate.

A History of Commercial Fires

Commercial fires have a long history – from London’s Tooley Street warehouse fire in 1861 right up to Belfast’s Primark…

Coopers Fire Moving Dates

Coopers Fire will be moving offices from Friday 13th March to Tuesday 17th March 2020.

Is it possible to build a fire proof building?

There’s never been a better time to build. Materials, construction techniques and fire safety have reached a pinnacle unthought of…

Is there a relationship between poverty and fire?

Around the world – in Manila, Rio de Janeiro, New Delhi, Cape Town – there are slums. These “informal towns” are…

Coopers Fire Exhibition Calendar for 2020

Coopers Fire will be attending and presenting at several different events in the UK throughout 2020. Check out this year's…

2019 in review: Year of heritage building fires and forest blazes

2019 was a busy year for fire. It struck notable world heritage buildings, like the blaze at Notre-Dame de Paris and al-Aqsa…

What can be salvaged after a fire?

Preservation of life is the fundamental goal of fire protection. In the immediate aftermath of a building fire, making sure…

Digital fire escape signage

Escape signage is a vital part of fire safety. It provides immediately recognisable cues to people in a state of panic…

Coopers Fire are exhibiting at Intersec Dubai 2020

From the 19th to the 21st January 2020, Coopers Fire will be exhibiting in the UK Pavilion at Intersec Dubai 2020.

2020: Architectural and design trends for a new decade

Cities and suburbs continue to grow, the climate continues to change and human beings continue to multiply. The next decade…

What’s the hottest temperature possible?

The colour of fire and its temperature are directly linked; red flames are cooler, blue flames are hotter. Acetylene and pure oxygen…

Find Coopers Fire at London Build 2019!

Coopers Fire are exhibiting at London Build 2019 on stand T40 from Wednesday 27th to Thursday 28th November 2019. Based in…

The future of firefighting

The world’s becoming warmer and drier. Water is becoming scarce. Forest fires are becoming more frequent and rampant. The future…

Fire safety in modern shopping malls

The rise of the shopping mall is no accident – but the idea of a high street over multiple floors, under…

Could artificial intelligence fight fire before it starts?

Social media bots, machine learning and virtual assistants. This technology drives industry and our day to day lives, and gets…

Coopers Fire are moving!

Coopers Fire are excited to announce they are moving to a new headquarters in April 2020. The new, purpose-built headquarters…

The Amazon Fires

Rainforest fires are not irregular; they happen all the time, usually following the seasons or under controlled and sanctioned land…

How to stop a fire without a fire extinguisher

While fire extinguishers are a common sight in offices, restaurants, factories and workplaces everywhere, they’re far less likely to be…

Are new build homes safe?

Modern homes are popping up everywhere, as housing attempts to meet demand. New builds are typically built with timber frames,…

Coopers Fire sponsor Hampshire Fire and Rescue Service

Coopers Fire are proud to sponsor Hampshire Fire and Rescue Service to complete a trek to above Everest Base Camp…

Apartment living: Fire safety

High rise living comes with risks – and it has clear advantages, too. It’s cheaper to buy a flat or…

In the know: Architects and fire safety

Although it often feels as though buildings spring up overnight, there are strict building requirements and regulations that need to…

The importance of fire safety in historic buildings

Historic buildings carry with them the weight of the past – and for better or worse, they’re ingrained in our…

5 tips for a safer home

Home is everyone’s most important place in the world – but sadly, fire destroys thousands of homes every year, and…

Could this non-toxic solution make wood fire resistant?

Wood is an excellent construction material. It’s been used for millennia to build everything from houses and boats, to weapons…

Coopers Fire launch new ResQ-Window at Firex International 2019

The new ResQ-WindowTM from Coopers Fire will be on display at Firex International 2019. Firex is at the Excel Centre, London on 18th to…

Fire safety at work: Minimising hazards

Safety at work isn’t always a guarantee. Some jobs, like firefighting or deep-sea diving, are more dangerous than others. For…

In the event of a fire: Creating an escape plan

Every household should have an escape plan in place, just in case. Although we all hope we will never have…

Coopers Fire exhibitions calendar for 2019

Coopers Fire will be present at a variety of different UK exhibitions and conferences throughout 2019. This will give you…

High rise buildings and preventing fires

It seems that the world grows a little bit taller with every building we create – especially in places like Dubai,…

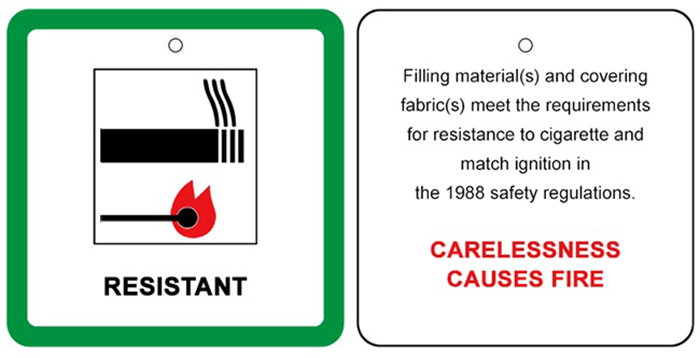

Stay safe: Furniture and fire safety

Every year, thousands of tonnes of perfectly recyclable sofas are thrown away for not having a fire safety label intact…

Coopers Fire to hold a 2019 Distributor Conference in Dubai

Coopers Fire will be holding a distributor conference in Dubai from Tuesday 30th April to Wednesday 1st May, 2019 The…

The challenge of building a robotic fire fighter

The 21st century has so far been a golden age for robotics. Drones, fledgling artificial intelligence, machines capable of four-legged…

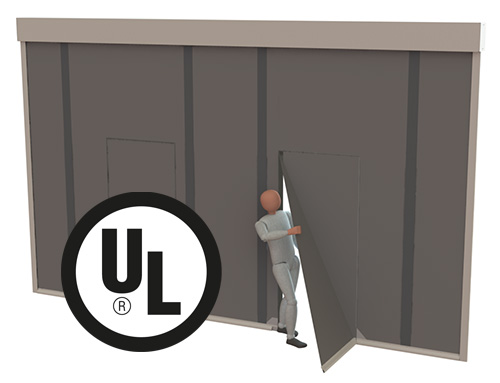

Coopers Fire gains further UL certification

Coopers Fire have gained further product certification to UL standards for the FireMaster Egress. UL is a global leader in testing,…

How do fires start?

Fire needs fuel, oxygen and heat, in the right combination, to occur naturally. If just one of those elements is…

The world on fire

In 2017, fires tore through the USA, Canada and Europe. In the summer of 2018, some of the deadliest wildfires…

Coopers Fire Exhibiting at Intersec Dubai 2019

Coopers Fire are exhibiting in the UK Pavilion at Intersec Dubai 2019 - 20th to 22nd January 2019.

What’s new in fire safety technology?

2018 was a year of wildfires, commercial building fires and even the tragic loss of a national museum. Fire protection…

Fire damage: What can a building survive?

Buildings are pretty tough. Most can stand for centuries with the proper care. Fire can be the end of even…

Stay safe: House fires rise in December

House fires during the Christmas period are particularly devastating – and sadly more likely to occur, thanks to additional lighting,…

Architecture trends 2019

What’s the next big thing in architecture? 2018 focused on eco-friendly designs and customisable homes – but trends are emerging…

The new and revolutionary FireMaster® Cleanroom fire curtain

Coopers Fire are pleased to launch an innovative and revolutionary fire curtain solution for cleanroom facilities. The new FireMaster Cleanroom…

Underground cities – future or folly?

In 1500 BC, an ancient civilisation developed an incredibly complex underground city – complete with escape routes and proper ventilation…

Coopers Fire listed with UL certification

Coopers Fire have a range of products that are Tested to UL standards. UL is a global leader in testing,…

Coopers Fire at the ISPE Annual Pharmaceutical Conference

Coopers Fire are exhibiting at the ISPE (International Society of Pharmaceutical Engineering) Annual Conference on Thursday 22nd November 2018.

Amazing things you never knew about fire

When you’ve devoted your existence to fire safety, you learn a thing or two about the phenomenon you’re trying to…

Staying ahead of industrial fires

Since the introduction of ‘The Regulatory Reform (Fire Safety) Order 2005’, fire safety today is at a much better standard…

Coopers Fire at Tough Mudder 2018

Coopers Fire took the Tough Mudder Challenge on Saturday 29th September to raise money for the Children's Burns Trust. We…

Get to know your fire extinguisher

Everyone is familiar with what a fire extinguisher looks like – they should be everywhere you go. However, being confident…

Why can’t we make fireproof buildings?

Specialist materials, insulation and compartmentation are all used to make buildings safer – but why can’t buildings be made completely…

What to do when fire breaks out in a large building

There are few thoughts more terrifying than being trapped in a burning building – especially a large structure like a…

Coopers Fire are exhibiting at London Build Exhibition 2018

Coopers Fire are exhibiting at London Build Exhibition 2018 at the Olympia Exhibition Centre, London.

How zone pressurisation works with fire curtains

When there’s an intricately designed zone pressurisation system in place, how will fire and smoke curtains affect the flow and…

How the proscenium has changed

For non-theatre types, you’ll probably know the concept better as the fourth wall – a part of theatre that has remained in…

Bringing the grand staircase back

The grand staircase plays an important role in the first impression of a building. The bigger the staircase, the more…

New managing director at Coopers Fire – David Cerquella

David Cerquella joins Coopers Fire as new Managing Director.

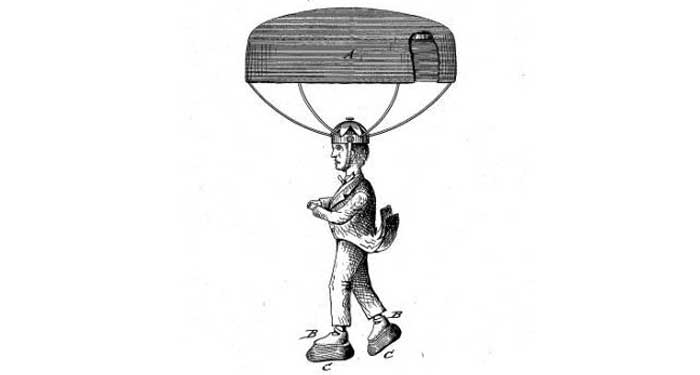

Unusual fire escapes

It’s amazing to think that fire escapes haven’t always been an important part of architecture and design – but prior…

Fires in films – what would really happen?

The movies – they don’t have to be accurate to be fun! Even fire safety experts like to watch films,…

A global construction boom

The world grows upwards every day, as new buildings rise from the ground. We’re always looking for more space to…

Lift safety in the event of a fire

You’ve probably seen signs in buildings telling you not to use lifts during a fire – but why? Couldn’t you…

Has space exploration saved our lives?

There are a lot of people who wonder why humankind has poured so much of its effort into exploring space.…

The new Qatar – Construction capital of the world

Qatar was once reliant on pearls. Before the 1940s, Qatar was excruciatingly poor – until oil was discovered. The country was…

Revolutionary fire safety

It’s strange to think that the modern household smoke detector was invented accidentally. That little stroke of serendipity has gone on…

Making a masterpiece: Louvre, Abu Dhabi

The Louvre Abu Dhabi is one of the most impressive and awe-inspiring structures ever built. It has achieved this without…

The speed of fire

Fire spreads at an almost unbelievable rate. Recently, forest fires around the world have highlighted how devastating and fast-spreading fire can be.…

The science behind the fire curtain

Fire curtains have revolutionised building design – making complex structures safer and offering new levels of fire protection for all…

Compartmentation for fire protection

Compartmentation for fire protection is a fundamental part of modern architecture and construction. Passive fire protection saves lives, property and…

Workplace annual fire risk assessments

Workplace fire safety is a critical aspect of business operations that every employer has to conform to. The alternative to…

Fire safety at Christmas: Home and office

House fires started by Christmas trees are thankfully quite rare – and thanks to better education and information, prevention and…

Dubai’s architecture: Land of skyscrapers

Dubai is the largest, most populated city in the UAE and the crowning jewel in the Persian Gulf. It was…

Industrial fire curtain manufacturer: Leading UK fire safety

Coopers Fire has been the leading industrial fire curtains manufacturer since 1983. We’ve used our decades of experience to develop new…

Premium fire and smoke curtains: Fire protection for landmarks

Historical landmarks are always a point of pride for their host city and host country. Think about the most striking,…

Using datasheets to install industrial fire curtains

Before any machine, component or device is installed in a project, it has to pass a great deal of scrutiny.…

Fire safety training with CPD courses

Continued Professional Development (CPD) is all about growth and building on expertise. Development doesn’t always have to be formal; personal…

Protected means of escape for modern building design

Modern building design has taken giant leaps since the days of the first architects. Today, the challenges facing our growing…

Fire curtains for openings in walls

When it comes to fire safety, is it important to consider both methods for the prevention and for the control…

Putting a stop to fire and smoke damage with bespoke design

Most fires are avoidable and can be safely mitigated with appropriate preventative measures. While there are plenty of reasons to…

What are fire rated curtains and why are they so important?

In the event of a fire, you may not consider a curtain to be an effective method of protection against…

Drop down fire curtains and modern architecture; a perfect match

Automatically deployable fire curtains or drop-down fire curtains can solve a number of different safety problems relating to the spread…

Fire Curtains recognised in latest edition of BS 9999:2017

Fire curtains recognised in latest edition of BS 9999:2017 referring to BS 8524.

Fire curtains vs. fire shutters. Which one’s for me?

It cannot be denied that fire safety in all types of buildings is of paramount importance for any project –…

Fire and smoke curtains for airports

Why Airports are at Risk of Fire Spreading As well as committing to the fire safety regulations that are required…

How to stop the spread of a fire with compartmentation

When investigating how to protect your home or business from the threat of fire, you may have come across the…

The best way to utilise fire protective barriers

During the construction of a building, it is a legal requirement to have a reliable fire safety procedure in place,…

Dubai: A brief history of the city’s struggle with fire safety

Recently, the construction industry has experienced rising growth throughout the world, particularly in the Middle East with demand increasing from…

Qatar World Cup: Coopers Fire’s Top Tips for Fire Safety

Over the next five years, the landscape of Qatar is expected to change dramatically, due to their successful bid to…

Fire Curtains in Dubai: A Coopers Fire Case Study

As an area experiencing an increase in economic prosperity, over the past few years, Dubai – among other cities in…

Qatar World Cup 2022: With 5 years till kick off, the need to design in fire safety is more apparent than ever

Following Qatar’s successful bid to host FIFA’s 2022 World Cup, Qatari economy has boomed. This success has visually translated into…

Aldgate Tower: A Fire Curtain Case Study

Fire Curtains Go Sky High Over the past few decades, there have been countless outbreaks of fire, especially with high-rise…

Fire Curtains for Schools – Coopers Fire Recommends

Why Fire Curtains are Essential For Schools In many schools, open-plan spaces are central to their functioning. For example, sports…

Why fire curtains for hotels are the perfect solution

What are Fire Curtains and How do They Work? Fire curtains provide both commercial and domestic owners unrivaled levels protection…

Compartmentation Fire Safety – Why it is Key

What is Compartmentation fire safety? Compartmentation involves the division of a larger space into smaller spaces. In the event of…

Benefits of having fire curtains in schools

Why Install Fire Curtains in Schools? Fire curtains and smoke curtains are, as their names suggest, curtains that prevent the damage and threat…

Fire curtains in schools: Keeping empty schools safe all year round

Many schools every weekend (and holiday period) find themselves being left empty. Unfortunately, an empty school – if not left…

Airport fire curtains are changing the way airports are built

In the past several decades, unfortunately, there have been several airport fire tragedies. These sadly could have been prevented or…

Coopers Fire new SmokeStop Concertina Smoke Curtain

Coopers Fire launch new smoke curtain - The SmokeStop Concertina

What is a fire strategy and why you need one

What is a Fire Strategy? Necessary in complex builds and commercially functioning buildings, a fire strategy is simply a general plan that…

Fire resistant curtains protect lift lobby areas

Fire Resistant Curtains: An Overview Fire resistant curtains afford unrivaled protection from the devastating effects of fire and smoke. They…

Should you install fire resistant curtains at home?

Fire safety in the home, whilst being of the utmost importance, is something that, unfortunately, not all households uphold. The…

Smoke curtains installed abroad

At Coopers Fire, we are wholly committed to advancing fire fabric technology in both commercial fire and smoke curtains. Our commitment has led…

Smoke curtains: How do they work?

Today, ensuring your property, business, staff and inhabitants are fully protected in the event of a fire is mandatory. One way to…

Fire curtain servicing assures a lifetime of safety

Fire and smoke curtains play a vital life safety role, so it is essential that they are well maintained. Smoke and fire curtain servicing is…

Smoke and fire curtains finally making open space safe

What are Fire Curtains? Fire curtains and smoke curtains are, as their names suggest, curtains that prevent the damage and threat from heat…

Fire curtains: Durable, reliable and effective

Why do you need Fire Curtains? These days, whenever and wherever a new building is built – commercial or domestic…

Commercial fire curtains overseas

At Coopers Fire, we are wholly committed to advancing fire fabric technology in both smoke and commercial fire curtains overseas. This commitment has led our engineers…

Fire Curtains for Boundary Protection and Tall Buildings

Coopers Fire explains how fire curtain barrier systems may be used to provide boundary protection to both new and existing…

Smoke curtain compartmentation: The SmokeStop

What Are Smoke Curtains? As the name suggests, a smoke curtain stops and controls the spread of smoke in a building. They…

Fire safety in the workplace: Service & Maintenance

Fire safety equipment, such as fire extinguishers, fire alarms and even fire curtains, on the whole, do not have an indefinite lifespan.…

Fire safety drill: An effective how to guide

A fire safety drill is a legal requirement in any workplace, public or commercial building. Under the Fire Safety Order of 2005 it became…

Fire safety in the home

Last year alone, over 200 people died in domestic fires. Clearly, fire safety in the home is of the utmost importance and…

FireMaster Concertina fire curtain: The ultimate solution

For architects today, with a marked rising popularity in large modern spaces, being able to ensure fire safety without having…

Fire curtain servicing: The rules and regulations

Smoke and fire curtains, being used in place of traditional non-load bearing walls or sprinkler systems, offer great flexibility to…

Fire curtains a fire protective fabrics

Innovations in building materials have led to major changes in the way buildings are constructed and how they operate. Developments…

Fire hazards in the office

There are many potential fire hazards present in all offices, no matter how clean or well maintained they are. Understanding…

Fire protection: Prevention is better than the cure

Fires can have a devastating effect on all buildings, especially when they are able to spread quickly and easily. By…

Fire curtains: The safest and most discreet solution

Fire Curtains: discreet, safe and durable If you are refurbishing an existing building or designing for new build, ensuring that…

Fire risk self assessment or external agency?

In the United Kingdom, fire safety legislation covers all commercial premises and places of work. It also applies to buildings to which…

A quick guide to fire-fighting equipment for businesses

All businesses of a certain size in the UK are required, by law, to complete a fire risk assessment. These assessments…

Assessing the best assembly-point location

When a fire breaks out in the workplace, it can be a terrifying experience, and there may only be minutes…

Top five workplace fire safety tips

It’s vital that business owners and managers have a good knowledge of how they can improve fire safety levels. It may…

Keeping your business safe at Christmas

The run-up to Christmas can be an extremely busy period for many businesses: There’s the rush to get everything finished…

The essentials of fire safety training

If you operate a business within the UK, you are required by law to have fire safety training in place for all…

Important considerations when purchasing fire curtains

First and foremost, your home is legally required to comply with stringent fire regulations, designed to help protect you and…

Fire fatalities in the UK decreasing

A recent report has revealed that the number of fatalities caused by fire in the United Kingdom is currently at…

Fire safety in licensed premises

A recent incident in a Yorkshire public house has acted as a sober reminder for owners of all licensed premises…

Fire Door Safety Week 2015

September has been a busy month for promoters of fire safety. Hot on the heels of the CFOA UK Business…

CFOA UK Business Safety Week 2015

The Chief Fire Officers’ Association will run its annual UK Business Safety Week from September 7th, 2015. With the goal…

Coopers Fire, the first fire curtain manufacturer to be fully BS 8524 Parts 1 & 2 compliant

Coopers Fire are pleased to announce we have achieved full compliance for the British Standard BS 8524 Parts 1 &…

The role of the workplace fire warden

Every workplace of a certain size should have at least one member of staff nominated to carry out the duties…

Coopers Fire Smoke and Fire Curtain Latest Installations 2000-2015

SINCE THE BEGINNING OF THIS CENTURY, COOPERS FIRE HAVE INSTALLED FIRE CURTAINS AND SMOKE BARRIERS IN A NUMBER OF PRESTIGIOUS…

Fire-door maintenance and the law

At any one time in the UK, there are potentially thousands of fire doors which have been left open. As…

A quick guide to managing escape routes

As soon as a fire has been detected and alarms have been sounded, all of the occupants of a building…

Minimising false alarms

The commonly held belief that many false alarms are caused by malfunctioning fire protection systems is simply not true. Rather,…

The control of flammable substances in the workplace

Under British law, all businesses are required to complete workplace fire risk assessments on a regular basis. Based on the findings of…

New fire safety measures for 2015

In a move that has been welcomed by those within the fire protection industry, the UK government has recently revealed…

Promoting business continuity with fire sprinkler week

Promoted by the Chief Fire Officers Association, the annual Fire Sprinkler Week took place between the 16th and 22nd of March…

Fire and smoke curtain requirements

When specifying fire curtains there are a number of factors that need to be considered which will normally be affected by…

Domestic fire curtains

Fire curtain barriers have been protecting major commercial and public buildings for many years now. Indeed, many of the nation’s…

A quick guide to passive fire protection

As many of the elements which make up the area of passive fire protection are already built into the structure of…

How to carry out a simple fire-risk assessment

Ensuring your business premises are adequately protected from the risk of fire is not just a point of law. It…

The fire safety order and your business

It goes without saying that a fire is detrimental to any business. Not only does it have the potential to…

Fire safety in the nation’s historic buildings

They are among the most treasured properties in the United Kingdom; buildings which are a part of the nation’s very…